NEW Liquid Application helps hold the line

When it comes to the US Military, if it floats, flies, drives or dives – it needs fuel, FAST. In building the worlds most advanced mobile refueling systems, the minds and talent at ISOMETRICS, INC met that call head on and have been taking it to the extreme, since 1973.

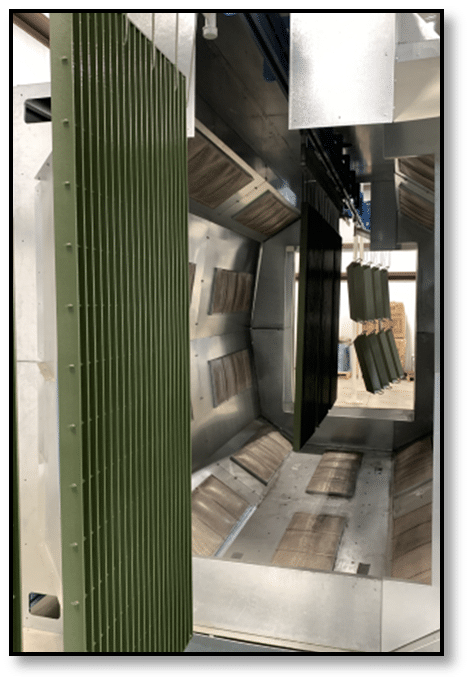

VULCAN™ had the recent honor of working with Ian Bracy and team on a specialized liquid paint line. Project specs included the ability to fully dry a wide variety of parts, energy efficiency, ease of use, reliability and an emphasis on minimal maintenance. After extensive interactive testing at VULCAN™ Labs, a few brainstorming sessions and some pencil sharpening, our team produced the perfectly optimized answer.

Solution:

When it comes to the US Military, if it floats, flies, drives or dives – it needs fuel, FAST. In building the worlds most advanced mobile refueling systems, the minds and talent at ISOMETRICS, INC met that call head on and have been taking it to the extreme, since 1973.

VULCAN™ had the recent honor of working with Ian Bracy and team on a specialized liquid paint line. Project specs included the ability to fully dry a wide variety of parts, energy efficiency, ease of use, reliability and an emphasis on minimal maintenance. After extensive interactive testing at VULCAN™ Labs, a few brainstorming sessions and some pencil sharpening, our team produced the perfectly optimized answer.

Efficiency:

When it comes to the US Military, if it floats, flies, drives or dives – it needs fuel, FAST. In building the worlds most advanced mobile refueling systems, the minds and talent at ISOMETRICS, INC met that call head on and have been taking it to the extreme, since 1973.

VULCAN™ had the recent honor of working with Ian Bracy and team on a specialized liquid paint line. Project specs included the ability to fully dry a wide variety of parts, energy efficiency, ease of use, reliability and an emphasis on minimal maintenance. After extensive interactive testing at VULCAN™ Labs, a few brainstorming sessions and some pencil sharpening, our team produced the perfectly optimized answer.

Client Comments:

“I visited multiple IR oven manufacturing companies to have a full understanding of the options out there and the product. I wanted to meet the teams and tour the facilities before making an investment. It was very evident that Vulcan IR is the markets best in all aspects…(Quality, Manufacturing, Service, and the most important part the impact on our business) It has been a game changer for our ability to process parts through the paint line not to mention the cost savings to cure parts.

Convection ovens cannot compete with this technology.. Do your homework and you will see!”

Ian Bracy / Head of Operations - ISOMETRICS, INC