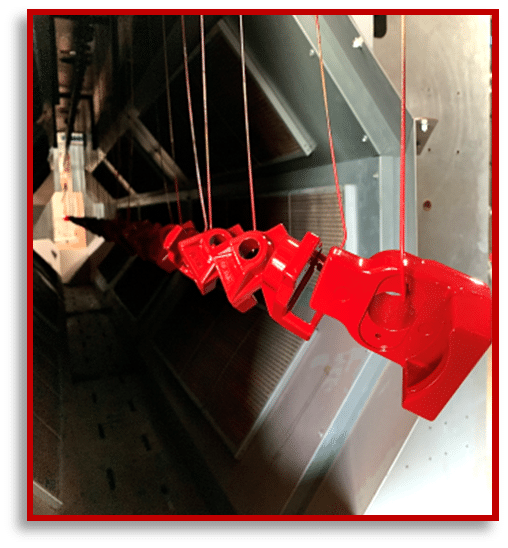

Heavy transport of goods is a key factor in meeting the huge supply chain & demands that keep America moving. The security of these goods is intrinsic for guarding against theft & ensuring precise schedules are kept. When it comes to the security of your tractor trailer fleet, the best manufacturer of Glad Hand, Air Brake and Kingpin Keyed Locks is JENDYK®- trusted since 1971. Having strong community values, they also recognized the need for school safety. Meet the K-I-S-T™ Lock CLASSROOM SECURITY line. A solid, yet simple & effective means of quickly securing classroom doors in emergency lockdown situations.

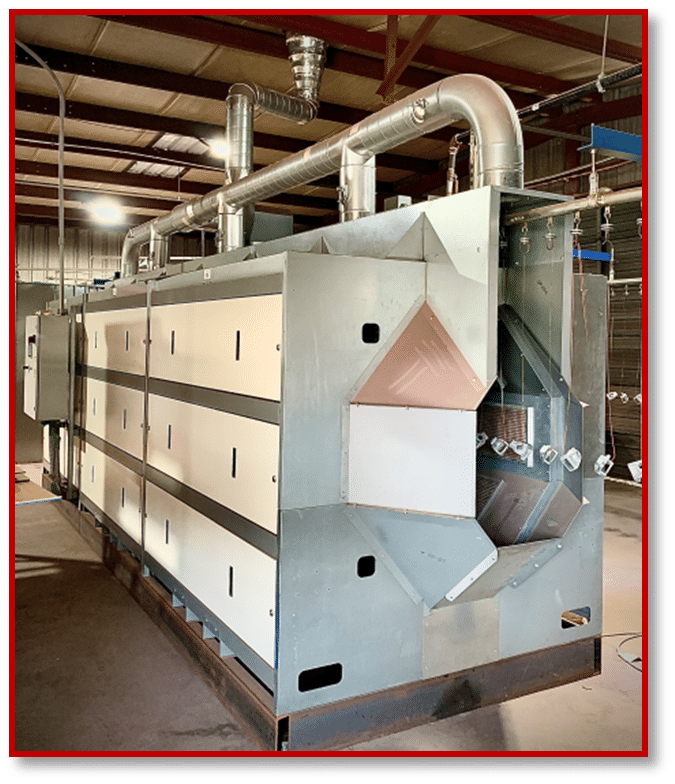

To increase throughput, provide repeatable finishes & lower operational costs, VULCAN IR™ designed a custom Gas Catalytic Infrared Curing Oven. Proving itself a smart investment, it continues to flawlessly cure thousands of quality JENDYK® parts for its clients- GRAINGER®, Northern Tool + Equipment®, MSC Industrial Supply®, Global Industrial® and McMaster-Carr®.

OVEN SPECS

- Compact, 21′-0″, 3 Module Cure Oven,

- Part Window – 18″W x 24″H

- 6- Heater Panels per Module that offer a total of 719,280 Max BTUs

- 9- Independently Controlled Heat ZONEs | Top to Btm | Ent to Exit

- Allen Bradley® HMI & Recipe Capable CompactLogix PLC

- Safe & Intuitive Rapid Response Gas Management

- STANDBY MODE

- Lowered Operational Costs

- Minimized Carbon Footprint

The engineered, custom design meets a rapid heat ramp within a micro footprint while doubling throughput & drastically reducing costs in direct comparison to their previous convectional batch curing system.

During a recent conversation with JENDYK® owner Bryant Lewis, he stated the IR system had actually surpassed his original expectations, “After a minor manufacturing adjustment, we are now able to run the IR oven on a single setting and line speed to either preheat or cure any of our parts.”