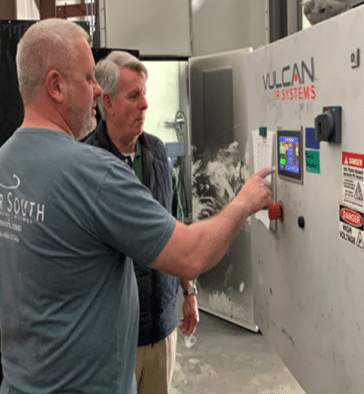

Stair South General Mgr, Kevin O’Brien is accompanied by Sam Torrey, Rep for Atlanta based integrator, Southern Fluid Systems as he demonstrates a recipe used for curing a new custom rail project. Known for being a high-end stair, rail and custom metal fabricator for both residential & commercial clients- reworks or downtime just aren’t an option. VULCAN IR accepted the task of creating a compact infrared powder curing powerhouse. Per O’Brien, the gas catalytic infrared oven has proven a positive investment toward Stair South achieving their supply and demand goals. In a short time, the team has more than doubled their line capacity, decreased handling times & continue to cure parts that meet their stringent levels of quality- all while maintaining surprising low operational costs.

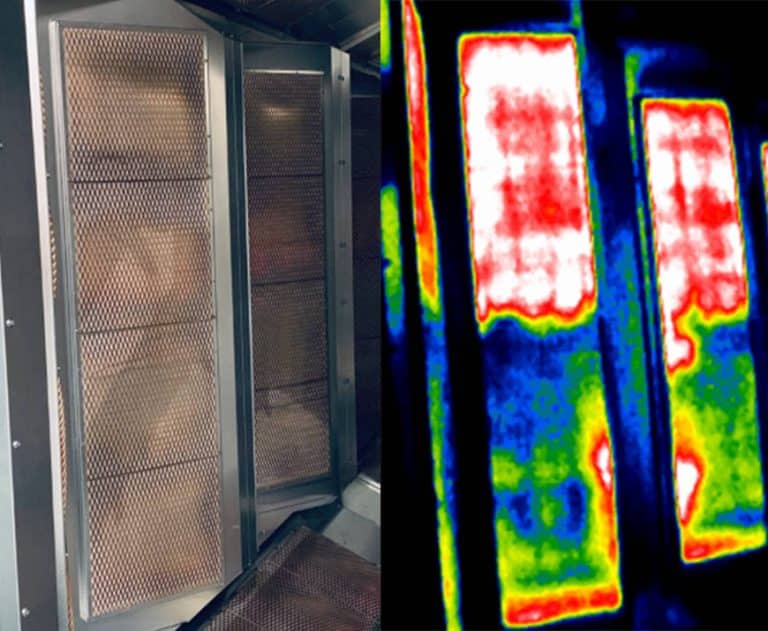

Equipped with its unique, vertical dual zone infrared heater panels, the VULCAN 12D Curing System offers superior control & increased power to part ratios.

Tangible Benefits Include:

- Advanced curing control

- Independent upper & lower heat zone controls

- x2 more power per module within same oven footprint

- Targets Leading & Trailing edges of complex parts

- Controlled Zoning

- Efficiency & Lower Operation Costs

21′-0″ Patented 12-D GAS IR OVEN SPECS

- 3ea- 7ft Modules: each featuring 8-Vertical & 4-Horizontal heater panels

- Floor Heaters: 3 ( Optional )

- Heaters: 39 Total units- capable of delivering 1,559,000 MAX BTU/hr.

- Part Window: 48″W x 96″H

- ZONING: 12 Independently & Controlled Entrance to Exit Heat Zones

- Controls: Quality Allen Bradley® HMI & Recipe Capable PLC

- STANDBY MODE